Atlas Extrusion System: Aspect x Warren and Mahoney

The Atlas extrusion system offers endless possibilities through the fusion of engineering and design.

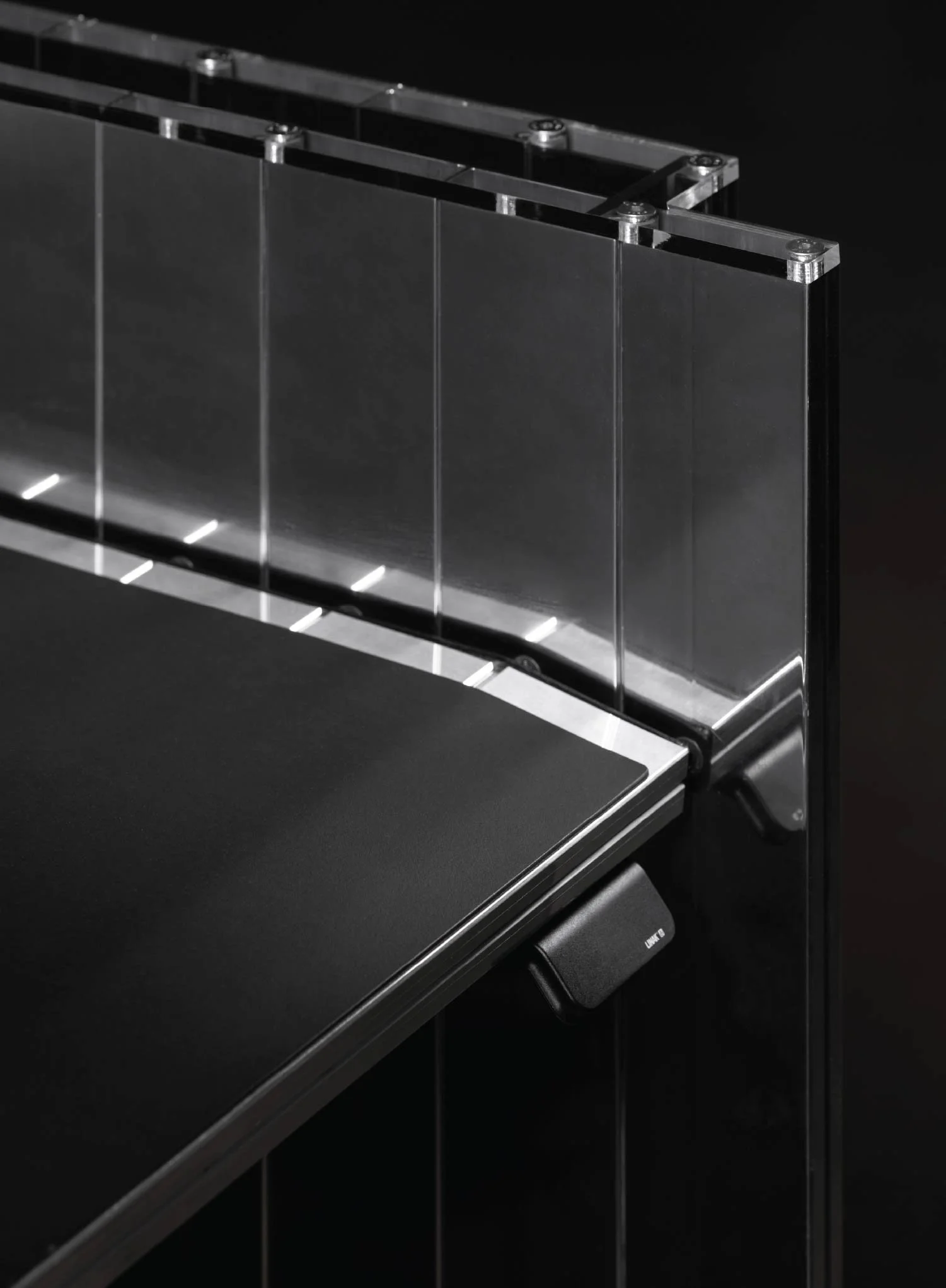

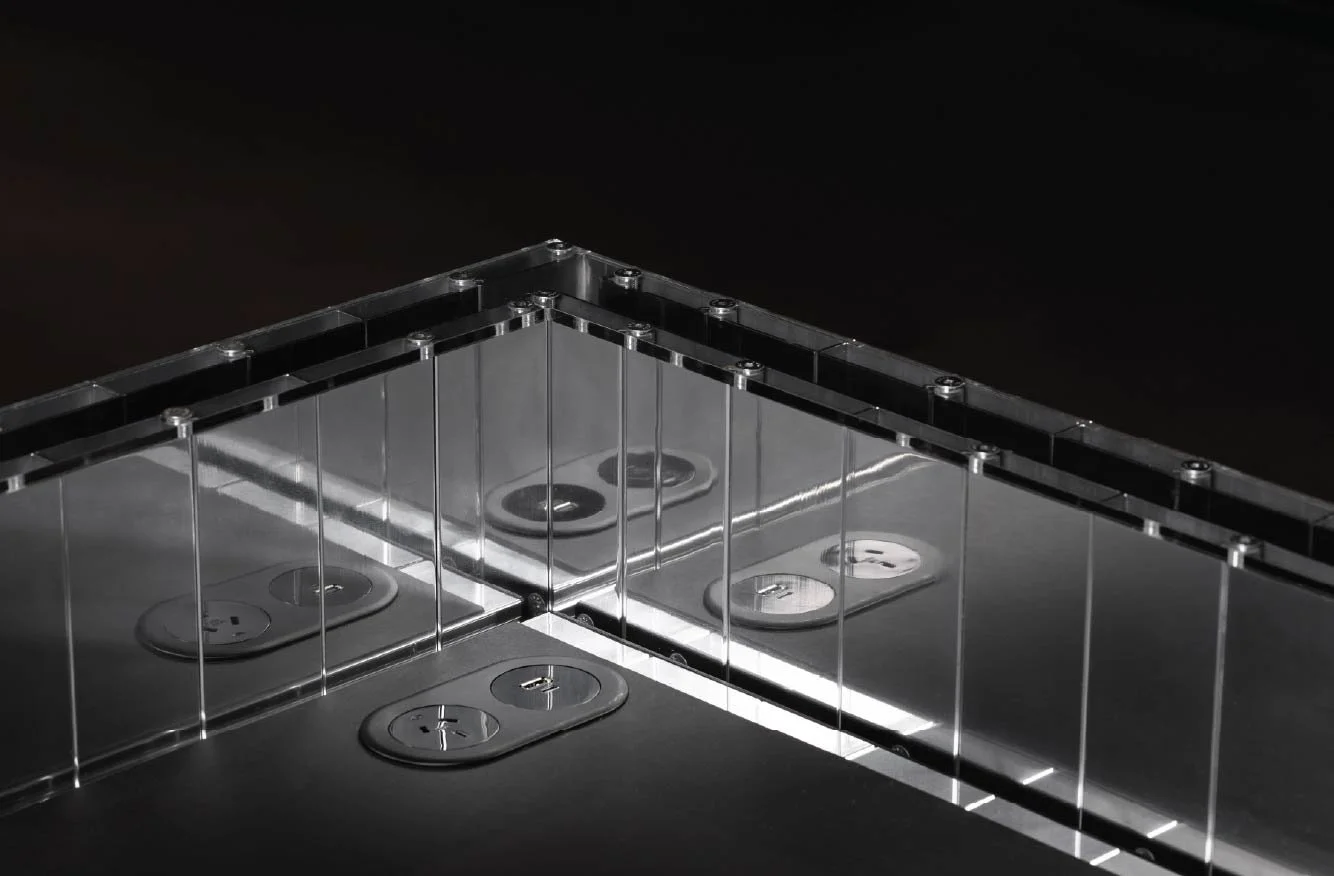

Inspired by the craft of metal forming, the Atlas extrusion system is an innovation in furniture engineering. Expanding on our comprehensive table collection, the system offers enhanced flexibility, scalability, and customisation for spatial design.

With its innovative method of interlocking aluminium profiles, Atlas introduces a refined modularity that immediately captured the imagination of Warren and Mahoney interior designer Daniel Kempka. Leveraging the system’s structural versatility, Daniel and the Warren and Mahoney team took a material-driven approach to designing a bespoke reception desk for the foyer of their Auckland studio.

To understand more about the journey from concept to completion, we sat down with Daniel who shares what he loves most about the Atlas extrusion system.

Why were you drawn to the Atlas extrusion system?

The Aspect team reached out and mentioned they had been developing something interesting—so we were instantly intrigued. Some initial prototypes of the extrusion system with its unique dimensions and connection capability were laid out in front of us, and while Aspect had designed the system for the column table product line, we suggested we could think bigger and bolder.

What made you think it had such potential?

The obvious flexibility of the system stood out. As an extrusion-based solution, its possibilities felt endless—made even more versatile by the connection methods Aspect had engineered. The timing was ideal, as Warren and Mahoney was reimagining parts of its existing Auckland studio, specifically the arrival space, with a renewed focus on identity and hosting.

Tell me about the design?

Its simple and honest. We wanted to take advantage of the simplicity of the system to highlight its technical charm. Our idea was not to over complicate or hide its story. Its pragmatic, utilitarian features are its strengths and we find these shared with our own design value of clarity.

Was there any specific inspiration behind the custom design?

Two key themes drove the design. First was pure pragmatics: it needed to be a dynamic device—a bench, a desk, a reception station. Second was the Atlas extrusion system itself. Showcasing it meant celebrating all its connections and fixtures as features, with an aesthetic style perfectly tuned to our approach: only the necessary.

How did this fit with your studio's aesthetic?

If you take a look around our studio, we celebrate the modern beauty and unapologetic nature of exposed structural elements. Shapes, angles and lines that draw attention to a contrast between formality and naturalness.

And it matches well with your space?

Absolutely, we wanted it to complement our studio space, but in a way that receded. We didn’t want it to stand out too proudly; rather, we wanted it to reflect the place, the work, and the people around it.

"Our idea was not to overcomplicate it or hide its story. Its simple, pragmatic, and utilitarian features are its strengths."

What was your creative process?

It started with that first meeting with Aspect about the idea for a new system and product. Once we understood the basics of the Atlas extrusion system and how its parts worked, we began testing ideas. We knew we had been offered a robust set of extrusion types, so it became about recognising opportunities to push the products limitations.

How did you develop the design?

We used our standard toolkit—sketching, modeling, prototyping, and in-house 3D printing—to explore the simple proportions of the system’s geometry. But to be honest, the system almost designed itself. With something so intuitive, there’s little negotiation needed. It was really about applying the functional aspects—like integrating the electric standing mechanism, which only reveals itself when curiosity leads you to discover how the whole thing actually works.

What did you enjoy about working with Aspect?

We enjoyed the innovative product development with Aspect and their in-house team who are also design enthusiasts. Their knowledge and manufacturing techniques easily accommodated our custom specifications, effortlessly turning concept into reality. We had the freedom to develop what we know was the most appropriate solution for us.

“Aspect’s ability to design and manufacture locally gave us the freedom to turn our concept into a reality.”

And your team love it?

Our team absolutely admire it. It’s a statement but at the same time it’s recessive. It has become part of our Auckland studio's visual fabric, which was the intention.

Warren and Mahoney has a strong professional working relationship with Aspect and their products, and particularity appreciate their abilities to design, manufacture, and supply locally—which proved to be a significant advantage throughout our many collaborative processes.

For more information about the Atlas extrusion system, see the Atlas product sheet.

View the Atlas table collection here.